Whether you're organizing a large-scale project, setting up temporary infrastructure, or need reliable shelter for equipment and operations away from the city, renting or purchasing a hangar may be the ideal solution. Arch-frame hangar structures provide a versatile and dependable option for a wide range of industrial and logistical needs — from field warehouses and equipment storage to emergency response centers and mobile workshops.

Engineered to withstand challenging environmental conditions, these hangars offer protection from wind, sun, and sandstorms, ensuring functionality and safety year-round. Quick-to-install lighting and climate control systems allow for a comfortable and productive working environment inside.

Thanks to their modular and adaptive design, TentProject hangars can be installed on virtually any surface — including concrete, soil, gravel, sand, or even rooftops and within existing structures.

Our hangars are made from galvanized steel and German PVC fabric with a density of 850 g/m². These materials ensure a lifespan of up to 15 years without loss of operational qualities. Additionally, the price remains affordable.

For sports organizations, we offer arch-shaped hangars with transparent inserts that can be used as arenas or football training facilities. Additionally, we provide mobile structures for events that can be rapidly assembled.

The tent covering made of German PVC can withstand temperatures from -50°C to +70°C, is non-flammable, and retains its color throughout its lifespan. An insulated version with an air layer can also be ordered for additional thermal protection.

Areas of application

Additional options

system

of toilet

disassembly

resistance

certification

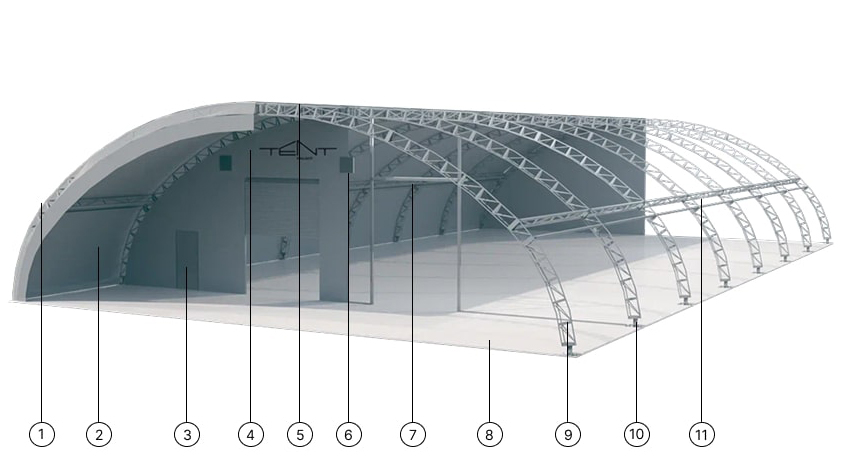

Hangar elements

Our hangars are engineered to withstand wind speeds of up to 35 m/s (126 km/h), which confirms their durability and stability. The structure is equipped with a tension mechanism that ensures perfect tensioning of the hangar's roofing on the truss structure, guaranteeing excellent tensile properties. Each hangar made of PVC and galvanized steel is completely free from wrinkles, scratches, dirt, and rust.

- PVC tent

- Wall

- Door

- Branding

- Side braces

- Ventilation

- Gates

- Floor

- Beams

- Support

- Skirt braces